Cost Saving and Environmental Protection Heat Shrink Tunnel

Earth Conservation with Spending Less Money

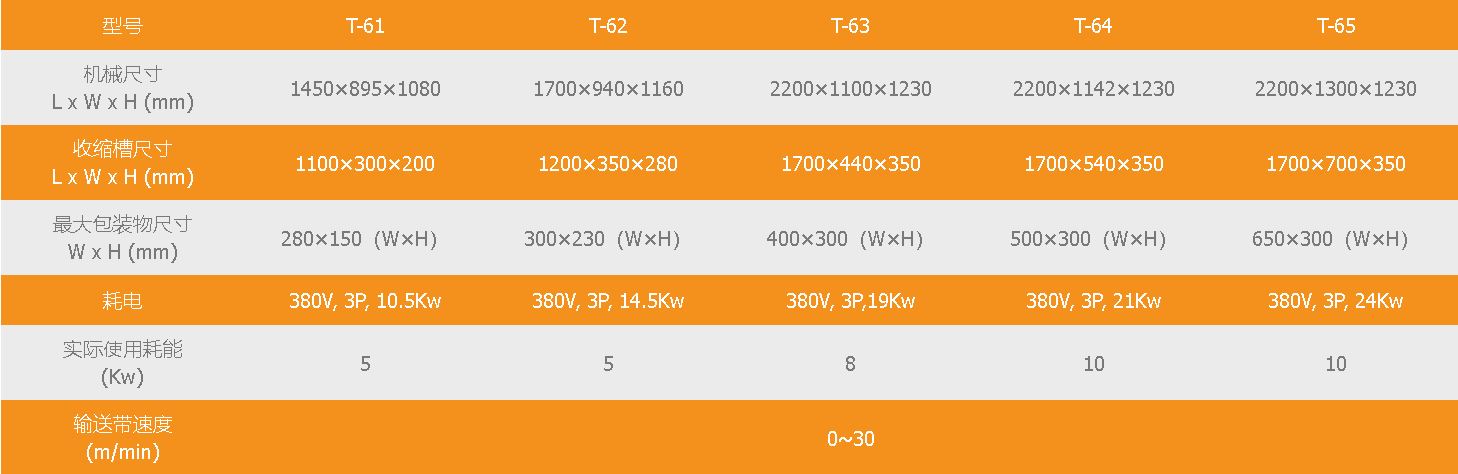

T-Series shrink tunnel produces consistent uniform film shrink using heavy-duty, variable speed blowers and heating elements. This combination creates a recirculating air system that forces air to all package surfaces. Independent control systems regulate temperature, air velocity and conveyor speeds. The efficient heating system on each machine reduces the amount of electricity and the cost of operation.