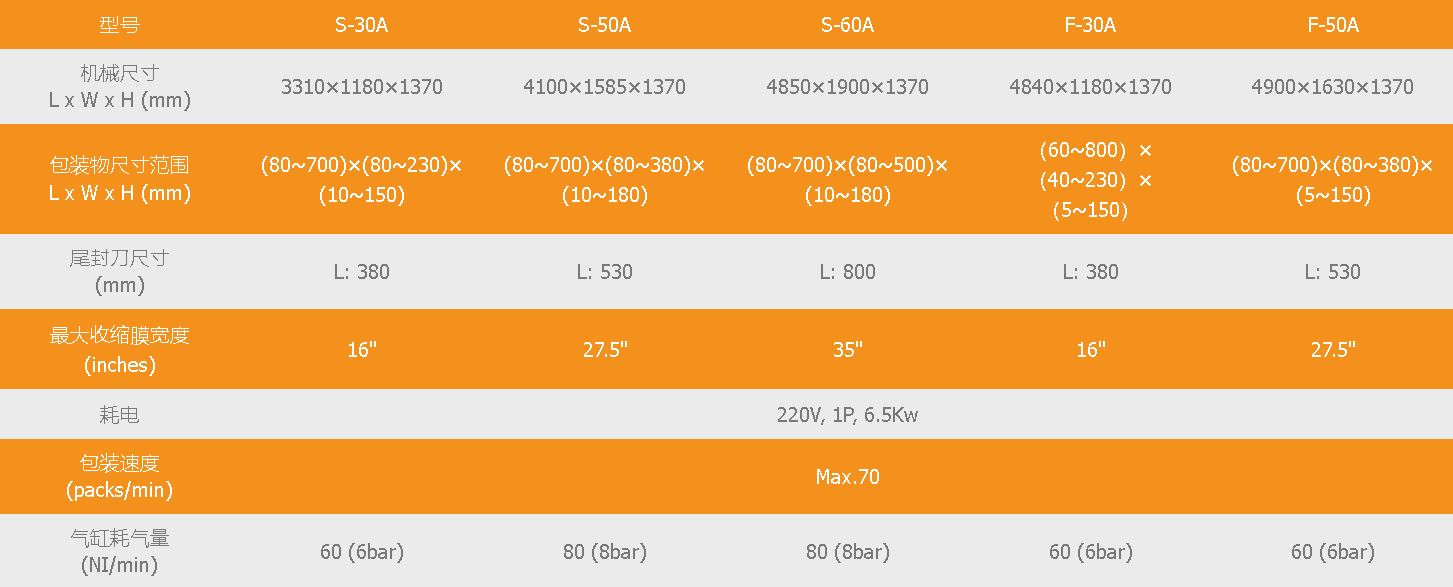

Versatile Economic High Speed Box Motion Side Sealer

Speeds up to 70 ppm.

Based on the servo driven mechatronics design continuous motion side sealer, this series machines offer a more economical packaging solution with servo controlled for customers. S-30A and S-50A can also be equipped by various kinds of infeed system to minimize the budget cost by increasing machine flexibility. This series is mostly suitable for contract packagers covering a wide range of applications.

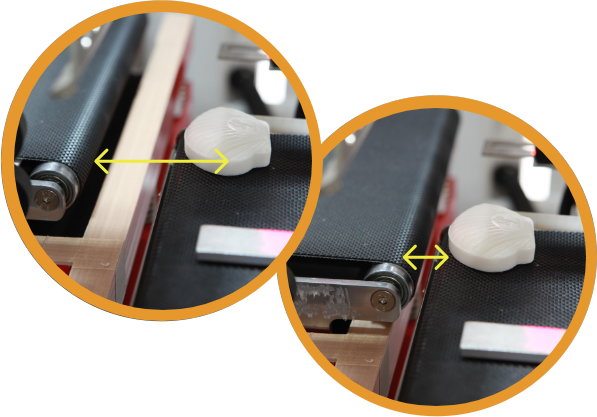

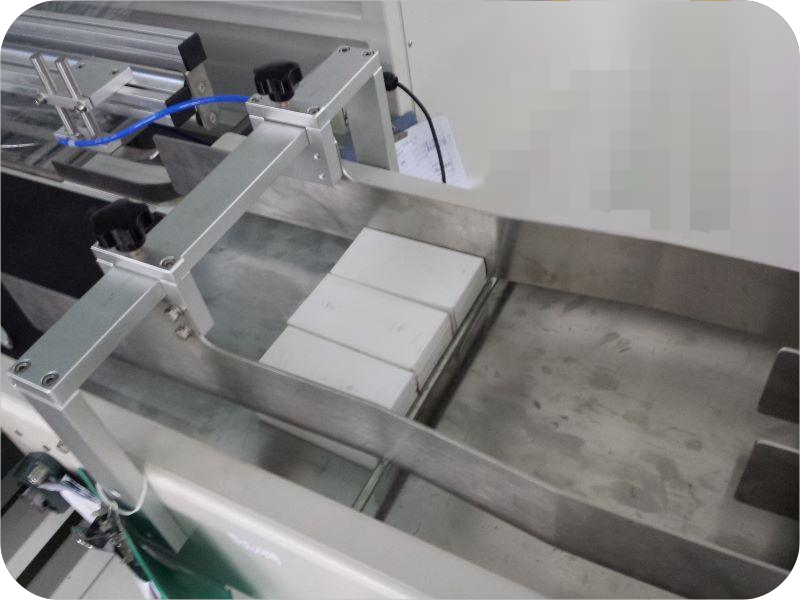

The distance between the front and rear conveyor belt can get closer for packing small products. When sealing happen, the rear conveyor will pull back for sealing bar to go downward.

Stainless steel machine are available allow the machine to be working stably under high moisture and low temperature working condition.

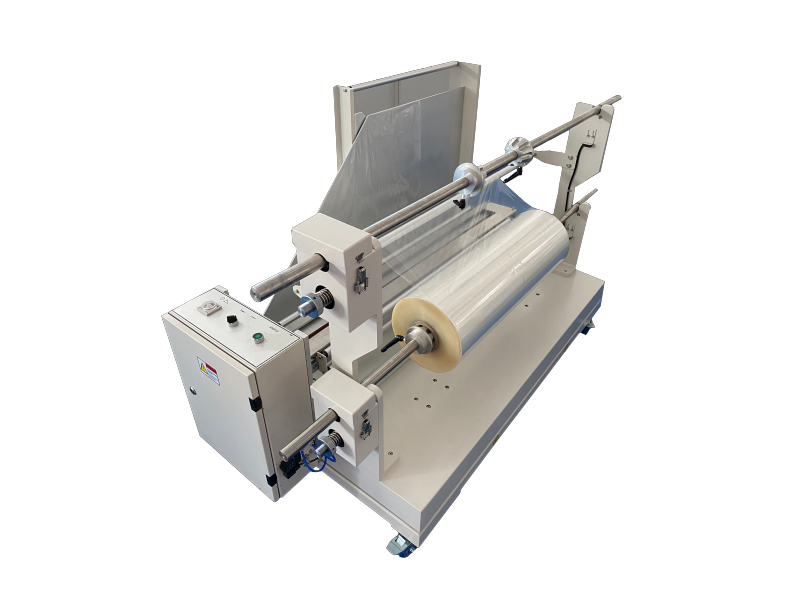

Devices to change single sheet POF films to center fold form. Save 50% of time to films changing to increase efficiency

Feeding devices with grouping function are specially designed to feed products to form a multi packing. Several products can drive together on the same time to prohibit misalignment happen. Packaging quality is improved because of this. It can increase production speed compare to feed multi products by hand. Connecting to the existing production line can accomplish a fully automatic production.

A guide rail pushing system is employed to pushing product in muti-packs format. Depends on products height and shape, different guide rail pushing systems are available.

Finger conveyor contains quick change flight lugs with stainless steel surface. With product guide rail, it is mostly used for driving a cluster to fit a wide range of products. Program connected to subsequent shrink wrapper and missing products detection is provided. Tailor made in different specifications are available